Project status: Finished project

Identification number: SGS12/178/OHK2/3T/12

Basic info

The goal of the project is the development of measurement, simulation, and experimental methods for a nontraditional energy supply with a high-speed synchronous generator powered with a turbine. The project covers partially the mechanical construction of the device, the problem of generator control, measurement of rotor position and possibilities of sensor less control. It also covers the optimization of power supply operation.

Currently, there is a constant increase in the cost of conventional energy sources, especially for the case of heating and electricity production. Therefore, research and application of various alternative energy sources is an interesting topic of current time, that should reduce costs but also reduce the burden on the environment. In connection with the previously solved projects – for example a high-speed generator driven by a turbine – appears to be a promising alternative source. In addition to sufficient electrical power (in the order of kW units), the device should also be able to produce thermal energy. In addition to application such as a sufficient power supply, for example, for a family house, the generator can work as a backup power source for emergency situations. In the field of high-speed machines, their design, control, measurement, and simulation; there are several current problems. If we omit the mechanical problems of the motor’s own design (which we assume is a purchased one), the problem in this area is mainly the connection of a suitable turbine as a drive and, especially, the sufficiently high-quality connection of both machines. The design of both machines as one structural unit seems to be the optimal solution, however, due to the very limited possibilities of the faculty equipment, it will be necessary to assemble the generator from two originally separate devices. Thus, in this area, the key current problem is the quality connection of both machines. A possible design of the complete set for further continuation of the project is considered for the coming years. Another current problem lies in the field of generator measurement and control. A digital signal processor (DSP) is currently used for control. The advantage is that control algorithms are well known, and relatively powerful hardware is sufficient for middle region of speeds. However, computing power is proving to be a weak point for high-speed motors (generators). As our experience with motor control up to approx. 40,000 rpm shows, there is no longer enough of computing power to implement the control algorithm. Therefore, one of our goals is to design a controller based on a programmable gate array (FPGA), which appears to be promising for better performance of control algorithms. Another current problem lies in the measurement area. The actual built of experimental workplace has a synchronous motor with permanent magnets for a maximum speed of 42,000 rpm. Relatively accurate information about the machine rotor is required for the correct function of the control algorithm. The resolver serves as a position sensor in the machine used. This is one of the factors limiting the maximum possible speed of the machine. Therefore, we would also like to try to find an algorithm for sensorless evaluation of the rotor position and its possible implementation. The last current topic, which we would like to address, is the management of the use of produced energy.

Project leader: Doc. Ing. Martin Novák, Ph.D.

Project goals

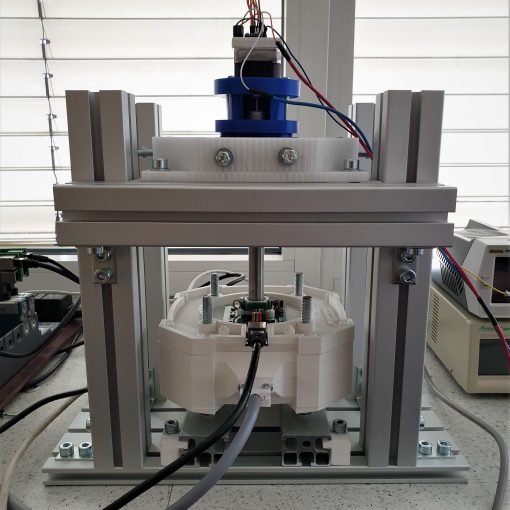

- completion of the experimental generator-turbine workbench

- tests of the generator under load

- FPGA-based controller design

- literature review of sensorless control algorithms

Expected project outputs:

- Functional workbench of a high-speed machine (generator + turbine)

- FPGA-based generator controller

- literature review of sensorless control algorithms

Specification of objectives for the second year of the project:

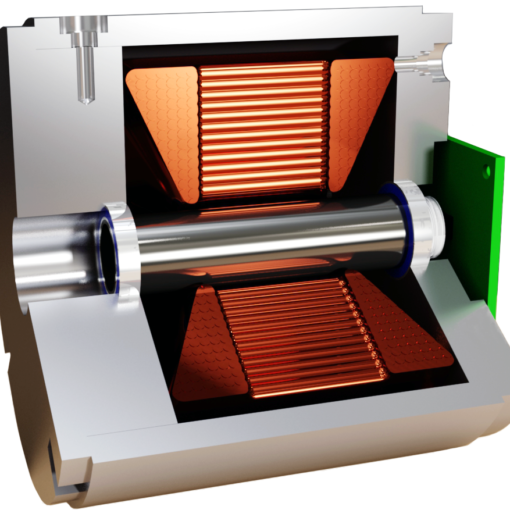

- measurement of magnetic properties of powder cores for the construction of a prototype of a high-speed motor (M.Novák, Z. Novák)

- manufactured prototype of a high-speed engine (M.Novák, Z. Novák)

- measurement of SiC switching element properties in chopper mode (M.Novák, Z. Novák)

- design of 3 phase converter with SiC elements (M.Novák, Z. Novák)

- system for automatic shutdown of the inverter when the maximum level of vibrations is exceeded (A. Kouba)

- literature review of diagnostic methods for cogeneration units (A. Kouba)